How Many Contacts Do You Need?

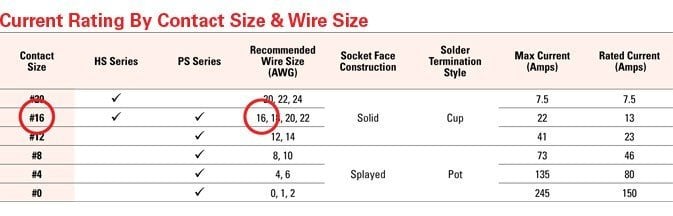

For example, let’s say we are trying to connect 3 x 16 AWG wires and 2 x 12 AWG wires. By looking at the table below we can determine that size 16 AWG wires require size #16 contacts, and that the size 12 AWG wires require size #12 contacts.

It is important to note that each connector series features a variety of contact sizes. Some may be the same size or termination type (crimp or solder) while others may not. For example, both HS and PS Series connectors feature solder contacts, but only the PS Series has a #8 contact available. HM has just #20 and #16 contacts.

Contacts Come in Various Sizes

| #16 contacts are recommended for wire sizes 16, 18, 20, and 22 (AWG) | |

|  |

| #0 contacts are recommended for wire sizes 0, 1, and 2 (AWG) | |

Selecting the Correct Contacts

The best way to determine if a connector series meets your wire and contact requirements is to view the contact specifications sheet. This document is available for every series both in the complete catalog and on each series webpage. In the example below, you can see a table listing the contacts and associated wire types for the HS and PS series of solder connectors

To learn more about contacts you can visit our Contacts page. Or, you can continue learning the steps to building a custom connector. Once we have established the contact sizes for our wires, we can proceed to the next step Select a Connector Series

Summary

- The number and size of wires you are connecting must be determined first

- Contacts are sized for specific wire sizes

- Not all conatct sizes are available in both connector series